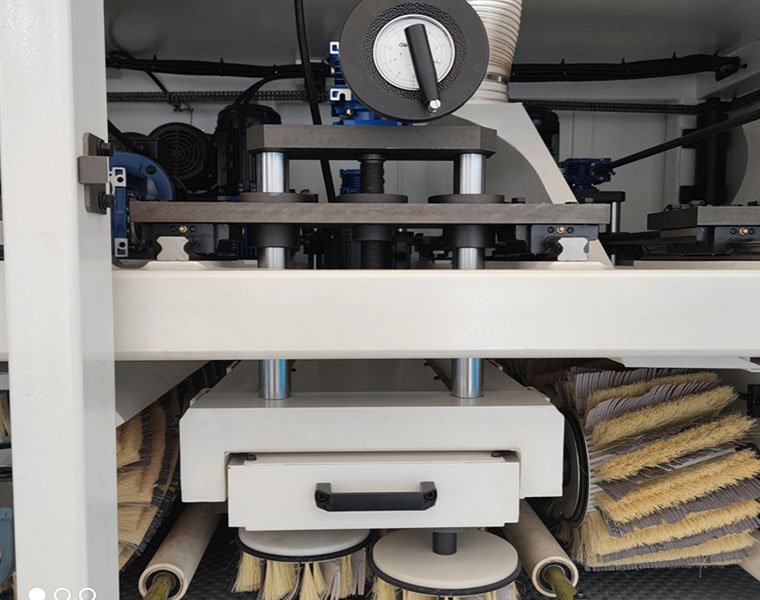

Brush sanding machine is the latest innovation in sanding technology, featuring cross brush rollers, sanding discs and longitudinal brush rollers. This configuration makes this sander a ideal finishing solution for doors, cabinets, shutters, face frames and other furnitures. Giantway brush sanding machine can do both white wood sanding or lacquer sanding by using different abrasive strips.

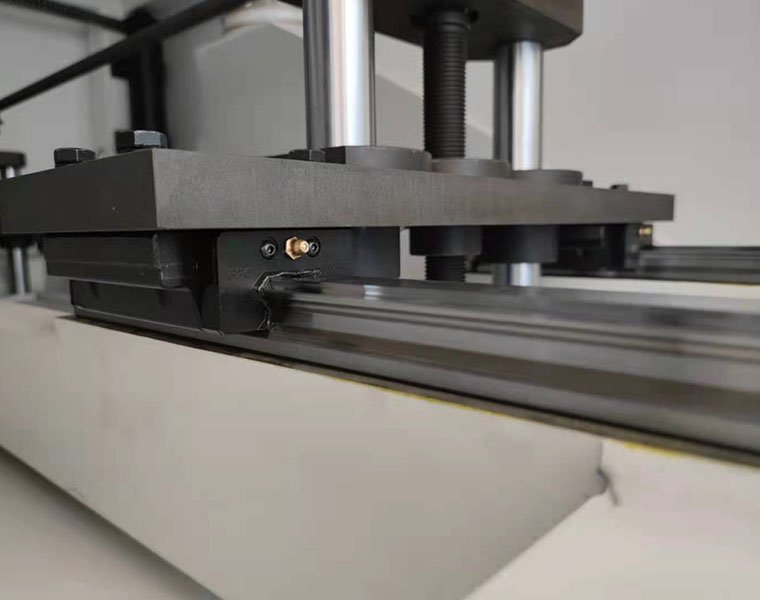

The YHS1100Z+X+W+W brush sander is engineered for versatile finishing applications, combining cross and longitudinal brush rollers with sanding discs to provide consistent sanding quality on both flat and contoured surfaces.

This model delivers uniform finishes for doors, cabinets, shutters, face frames, and other woodworking parts. Its multi-unit design adapts effectively to a variety of surface profiles.

By selecting different abrasive strips, this brush sander supports both white wood sanding and lacquer sanding, making it suitable for diverse production needs.

Integrated press systems and safety devices ensure stable feeding during operation, reducing interruptions and enhancing overall production efficiency.

Yes. With the correct abrasive setup and regulated feeding speed, the brush sander achieves smooth lacquer sanding and reliable raw wood sanding results with minimal defects.

Absolutely. The combination of cross and longitudinal rollers gives this machine excellent adaptability to grooves, curved profiles, and shaped edges.

Use finer grit abrasive strips for lacquer sanding applications.

Ensure appropriate feeding speed to maintain surface quality.

Regularly clean brush rollers to maintain consistent sanding performance.

Ideal for high-end furniture finishing lines, especially for detailed and shaped wood components requiring stable and even sanding results.

MODEL SPC ITEM | YHS1100Z+X+W+W |

Working width | 100-1100mm |

Working thickness | 10-100mm |

Cross brush rollers speed | Max 550rpm (inverter) |

Sanding discs speed | Max 500rpm (inverter) |

Horizontal brush rollers speed | Max 550rpm (inverter) |

Cross brush rollers oscillating frequency | Max 30times/min(inverter) |

Discs station oscillating frequency | Max 30times/ min(inverter) |

Horizontal brush rollers oscillating frequency | 60times /min |

Feeding speed | 0-19m/min(inverter) |

Cross brush rollers diameter | 320mm (8pcs) |

Sanding discs diameter | 180mm (11pcs) |

Horizontal brush rollers diameter | 320mm (4pcs) |

Total motor power | 23.86kw |

Feeding motor | 4kw(inverter) |

Cross brush rollers motor | 1.5kw |

Cross brush rollers oscillating motor | 0.75kw |

Horizontal brush rollers motor | 1.5kw * 4 pcs |

Horizontal brush roller oscillating motor | 0.37kw * 2pcs |

Discs motor | 1.5kw |

Discs qty | 11 pcs |

Discs station oscillating motor | 0.75kw |

Working units rise and decline motor | 0.75kw-4P |

Press rollers rise and decline motor | 0.37kw |

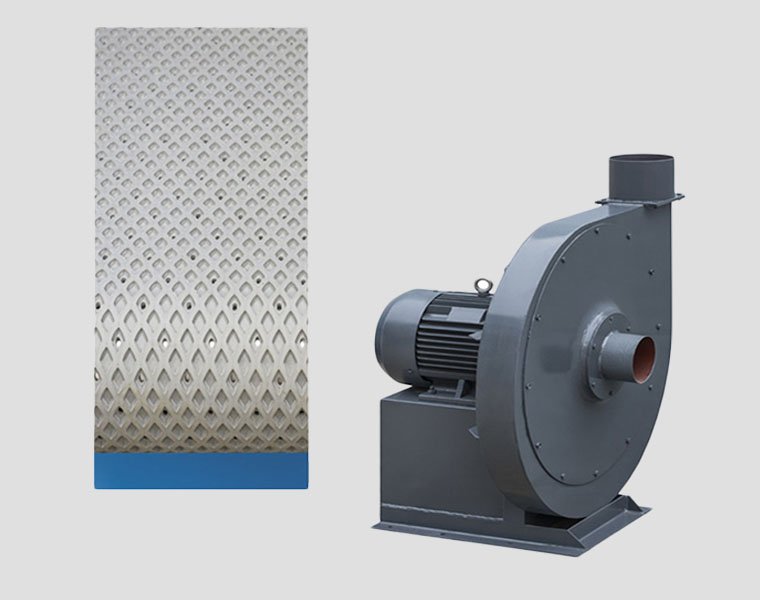

Vacuum pump motor | 7.5kw |

Dust outlets | 150mm*4 |

Vacuum table exhaust outlet | 200mm |

Overall dimension | 4000*1900*2200mm |

Weight | 4900kgs |